Blog

Screw Pile Foundations For Tiny Houses And Backyard Offices

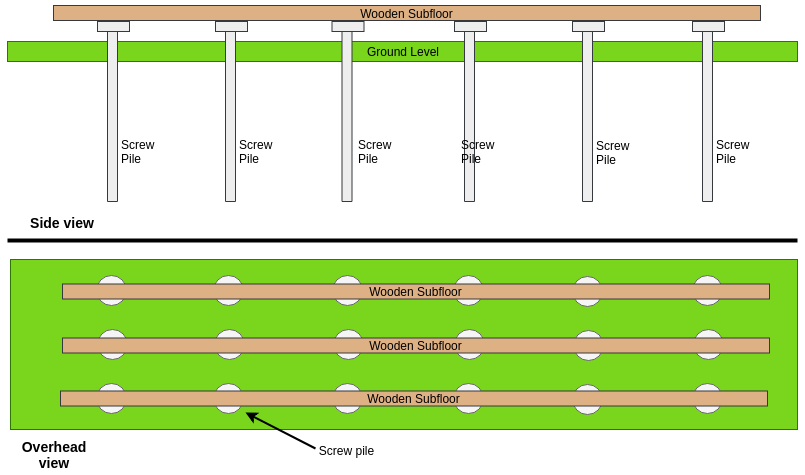

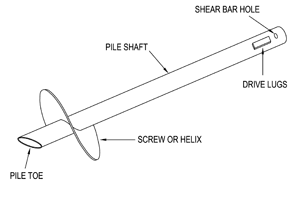

If you have not heard about screw pile foundations, imagine getting a gigantic screw (with a flat head) and screwing this into the ground. If the screw is thick enough, and goes into the ground deep enough, logically this will provide a fairly stable base for building on top of – especially when you have lots of them at regular intervals:

Thankfully screw piles are a great invention which can be used successfully for tiny house and backyard office builds, meaning much quicker early-stage build times. They also cost less than concrete foundations, and are better for the environment too.

Screw piles are also sometimes referred to as screw anchors, helical piles or helical anchors, although to prevent confusion we will tend to just say ‘screw piles’ in this article. There are quite a few advantages to screw pile foundations, especially for smaller buildings like tiny homes and backyard office projects, so we wanted to explore this construction method with this article.

A Closer Look At Screw (Helical) Pile Foundations

If you think of a screw, if is fairly thin compared to the material it is being screw into. However because it goes into the material quite deeply (relative to how thin the screw is), the screw ends up providing a good, strong fix.

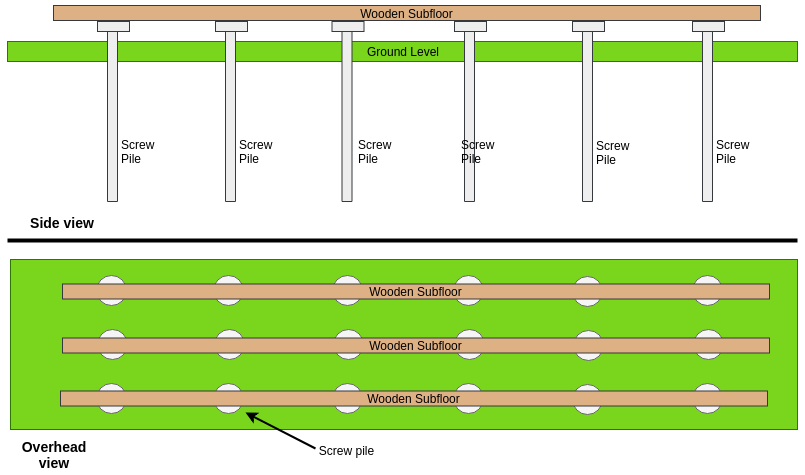

The idea behind screw piles is essentially the same: by getting very large screws and screwing them deeply into the ground (using specialized machinery), that will provide a good, strong foundation to build on top of. Screw piles have a sharp pile toe at the bottom which helps it initially grip into the ground, and then the screw/helix will move any earth out of the way (upwards) whilst the screw pile is being screwed into the ground:

As you will notice, there are shear bar holes which allow for another screw pile to be bolted onto the end of the current pile. This is because the deeper the piles go into the ground, the more secure of a foundation the system gives (similar to deep concrete foundations).

Screw piles have been around since the 19th century, with lighthouses being a common usecase: very long iron screw piles would be screwed deep into the sea bed, providing a solid base for the lighthouse. These would corrode, however, and they also had poor load and tension bearing capability. As a result, most screw piles nowadays are steel and hence they do not corrode in the ground, plus they have good load/tension bearing. Some companies are also exploring composite materials for their screw piles, which produces good results but they can be more expensive.

Screw Pile Foundation Building Codes

Screw piles are a perfectly safe method of construction, even for a two-story house. Many modern screw piles can support 70,000 lbs (31,750 kg) of weight per pile, which is much higher than concrete piles that typically support 5,000 – 30,000 lbs (2,270 kg – 13,600 kg) of weight per pile. And we have probably all seen structures such as houses which are supported by concrete piles.

Naturally we cannot cover every single building code option in this article, so we always advise that you check with your local zoning/planning office about screw piles. Having said that, however, screw piles are a perfectly usable option and most screw pile companies will work with you and ensure that the foundation system they supply and install will meet the relevant building codes.

In addition to this, international standards talk about screw piles in section 1810.3.1.5 and the NYC Building Code also mentions them:

- “Helical [screw] piles shall be designed and manufactured in accordance with accepted engineering practices to resist all stresses induced by installation into the ground and service loads.”

- “Helical piles may be used to support axial compression, or resist axial tension and lateral loads… Design of helical pile foundations shall be based on a geotechnical investigation… The allowable load of helical piles shall be in accordance with the applicable provisions”

Which is all just a fancy way of saying that screw piles are specifically considered an acceptable option for foundations in many building codes, as long as they are installed properly and sufficiently for the ground and planned building (which naturally applies to any construction method).

Speed Compared To Concrete Foundations

Concrete foundations can be quite time consuming (and expensive) because the process involves digging out a hole for the concrete, constructing any shuttering/forming structures as needed and carrying out the actual pour… before removing the shuttering/forming during the 1+ week curing process. And, of course, you cannot build until after the 1+ week waiting time because other the concrete has not reached sufficient strength yet.

In the video earlier, the American Builder says the process of just digging the hole and pouring the concrete (i.e. not including any curing time) would be “4-7 days” for a backyard office or tiny house, meaning that you would have to wait 11-14 days with concrete foundations before any building work could begin.

With screw piles, the video says that the pile system would be complete (to support a tiny house) in just half a day: a significant time saving. Postech Screw Piles agrees with this assessment, saying that they can often fit their screw pile system for smaller buildings such as backyard offices and tiny houses in “just a few hours”.

And of course, once the screw piles are installed, they can be built upon straight away: there is no week-long waiting process.

Costs Compared To Concrete Foundations

The process of creating a concrete foundation (outlined above) is not just time consuming: it can be expensive, too. Typical costs for a third party company to come in and dig the hole, construct (and dismantle) the shuttering/forming, doing the concrete pour, and removing any leftover earth can easily be $10,000 or more for a tiny house and $5,000+ for a backyard office.

In comparison, a screw pile system should work out cheaper because you might only need 4-10 screw piles (depending on the size of your project) and each screw pile can cost anything from $200-$800 per pile (including installation). We know that the price range is quite large there, we cover this more later. But assuming you get a decent price screw pile installation at $350 per pile and your tiny house needs 8 piles, you will be looking at $2,800 in total: much cheaper than what a full concrete foundation solution would end up costing.

Okay, so you will probably be wondering about the price range… how can it go from $200/pile in some areas to $800/pile? Well the simple answer is unfortunately that screw pile price calculation is not simple! The main factors for pricing up screw pile jobs are:

- Required depth of pile.

- Screw pile type (steel or a composite material, for example).

- Screws/helixes per pile.

Some of these requirements can only be determined after the screw pile company comes out and surveys the ground, which will probably involve them boring into the ground to carry out a geotechnical analysis, a survey that mainly considers things like soil type, how hard (or soft) the soil is, where the frost line would be etc. With this data to hand, they can then ensure that the correct pile type and configuration is used, along with getting the right depth based on the load requirements for the project.

Of course, if the pile company has done similar jobs in your area fairly recently, they might be able to give you a fairly accurate ballback estimate based on previous geotechnical boring surveys and similar jobs they have undertaken.

The best thing to do would be to contact a fairly local screw pile company (even if they are a few hundred miles away) and ask them whether they are able to give a rough estimate for your project. Like pretty much everything in life, there are expensive companies and cheaper companies out there (but the cheaper ones do not necessarily mean worse quality), so do not be put off if the first estimate you get works out at $800+ per pile: just try contacting other companies.

Pros/Cons

Screw piles are a great foundation system for many types of buildings, but especially for backyard offices and tiny houses where a full concrete foundation can often be overkill. Although there are of course some flaws with screw piles, too, which this section covers.

- Pro: piles are installed with very little impact to the landscaping or local environment: the process of installing them only creates a small hole, which will throw up small amounts of earth as the screw piles go deeper into the ground. However this is substantially less impact than digging a large hole/trench for concrete foundations.

- Pro: the overall environment cost is lower with piles, as well, because whilst the screw piles do need to be manufactured and transported, this is far better for the environment than working with concrete (concrete is particularly bad for the environment, especially due to the cement content, with lots of carbon emissions being released during its production).

- Pro: screw piles can be recycled by being screwed back out of the ground and reused with little or not disruption to the local landscaping/environment, nor to the actual screw piles which should be almost as ‘good as new’.

- Pro: as we explored earlier on, they are quicker and cheaper to install (on average) than concrete foundations. Who wants to wait around for 14 days for concrete foundations to be dug, poured and cured when you can just screw into the ground and start building on the same day?

- Pro: it is much easier to get down to a very low depth – even 200 foot/61 metres – with screw piles (if you really need to go down that deep) than with pretty much any other foundation system. This means that they can be a great, low(er) cost alternative if the local conditions require a deep foundation.

- Con: you will probably need to get a third party company in to install screw piles, which means paying specialized labor costs per hour that they are on-site. If you are able to dig and pour concrete yourself, however, then doing this yourself might save you money overall compared to hiring out a screw pile company.

- Con: whilst screw piles are perfectly safe to use, their use in buildings is still somewhat rare today. So you might come across ignorant architects, planning officials and builders who say that they are unable to work with your proposed screw pile system.

- Con: because their use is not as widespread as other foundation systems, you might have to pay a premium if you do not live near a screw pile supplier/installer. This could even mean that the overall cost would work out more than concrete-based foundations in some cases.