Blog

What Is The Best Insulation To Use In A Tiny House?

Insulation is a special layer of material which is put in-between voids (such as walls, ceilings/roof and the floor) that moderates the indoor temperature. Having a properly insulated tiny house is very important as it helps to provide comfortable living in both summer and winter. This is because quality insulation will prevent warm air escaping outside in winter (making you feel cold), but in the summer it will also stop overly hot air from outside coming into your tiny house (making you feel too warm).

We recommend 3.5” foam board insulation between your external walls and 3.5” fiberglass batts insulation between internal walls. Roof/attic insulation should be as thick as possible. What insulation you should use also varies depending on where in the country you live.

This article takes a detailed look at the different insulation types available for use in your tiny home. We also have a comprehensive (and free) guide on how to install insulation in the different parts of your house.

Different Insulation Options

There are quite a few insulation options, some of which are mainstream and can easily be purchased from Home Depot or Lowe’s. Other options are less common, either because they are specialist options (and usually expensive!), or simply that they do not work very well. We cover a range of different insulation types below that you might want to use in your tiny house:

Batts (fiberglass) Insulation

This is the most common option: using rolls of soft/’fluffy’ insulation (which is fairly itchy) between walls, floors and ceiling cavities to reduce empty spaces and increase your home’s overall insulation. It is made by mixing sand and glass together, which is then bonded via heat in a process similar to making cotton candy. The main benefits with fiberglass insulation is that it is easy to buy, cheap, lightweight and is easy to install. However it offers some of the worst insulation properties (it has a low ‘R value’ of R-3.2/inch) and it can compress down if not tacked into place (which is not ideal if you frequently take your THOW on the road). It can also be a hazard to your skin and lungs when installing it, so be sure to cover up and wear a face mask.

Denim (Cotton) Insulation

For fans of environmentally friendly approaches, recycled cotton from denim (and other sources) offers an eco-friendly way of achieving fairly good levels of insulation (up to 10% better insulating properties than fiberglass). However denim insulation tends to be denser – hence weigh a lot more – than batts, and the source of the cotton can be from high-chemical areas (such as farming byproduct) if you buy the cheapest denim insulation.

Concrete Block Insulation

Concrete (cinder) blocks can be useful for building large walls and buildings quickly, whilst giving a high level of sturdiness. Whilst they are often solid throughout, you can get cinder blocks which are ‘hollow’ – they will have gaps in the middle of them. These make them cheaper to buy and lighter to handle, but they also allow for high quality insulation to be put in these gaps. Such insulation will achieve a higher overall level of insulation than just having a solid cinder block: from R 1.11 for the solid block (a very low rating) up to R-13.5 for the completed, insulated-block wall (this is a pretty good rating – more than the R-11 which a 3.5” timber wall with batts insulation).

Concrete blocks will not be useful to you if you are building a THOW, but they are becoming more popular for fixed buildings – i.e. tiny houses on a foundation base. Of course, your walls with this approach will end up thicker than traditional thickness tiny house walls, which is something to weigh up.

Foam Insulation Board – Polystyrene

Foam insulation board is also sometimes called rigid board insulation, because it is a big, thick sheet – or board – of insulation which contains some form of plastic-based material to provide insulation. We split up the type of plastic below, because the plastic used does have an impact on the quality of insulation. However whichever type is used, the gist is that the R rating is better than batts insulation, but at a higher overall cost. Sometimes foam board can be double the price of simple batts insulation.

For example, polystyrene based insulation boards can include expanded polystyrene (EPS) which offers an R value of 3.8/inch (this is essentially re-used packaging material) up to 5/inch for extruded polystyrene insulation (XPS) which includes more manufacturing and processing than EPS boards.

Foam Insulation Board – Polyurethane

Known as PUR boards, they have an aluminum foil backing and are made by mixing chemicals and a ‘blowing agent’ to make lots of very small, low density bubble pockets in a closed cell which help to deliver a high level of insulation quality. The design also means that it has fairly good protection against water and moisture vapor, even though water-proofing (when used externally) or dry-lining (when used internally) is still naturally needed.

Foam Insulation Board – Polyisocyanurate

Also called ‘PIR’ or ‘ISO’ insulation, these offers one of the highest levels of insulation – R-6.7/inch – and they are foil faced which help to prevent moisture and air ingress. PIR boards are fairly light and are more eco-friendly than polystyrene and PUR boards, however they are expensive and their R value can decrease a little bit over time due to off-gassing.

Open Cell Spray Foam

If you have watched home renovation programs, you might have seen someone in a whole-body white suit with goggles and a mask spraying into wall/ceiling cavities. This is spray foam insulation, and whilst it is more of a specialist (and hence expensive) option, it can lead to a good level of insulation. It is also perfect for insulating areas which are hard to access, or are not ordinary, level surfaces (such as curved walls/ceilings). All forms of spray foam insulation should be carefully installed because it can be toxic due to the chemicals involved.

Open cell insulation means that the individual gas pockets connect in some way, meaning that there can be a small movement of air (at the micro level) around the insulation, lowering its overall insulating qualities. This is the cheapest form of spray foam insulation, offering a 3.7/inch R value and it also offers a good level of sound insulation.

Closed Cell Spray Foam

Dense closed cell insulation leads to a much higher level of insulation, at a 6/inch R rating. This is because each pocket of air is smaller/compacted, and they are not connected to each other: meaning less movement of air within the insulation, and thus less heat can get through the insulation. Due to its increased denseness, closed cell insulation is also good at reducing air leakage and keeping out pests. Just like open cell spray foam, this also is hard to install correct (even though ‘at home’ kits can be rented for DIYers) and it is worth getting a professional to do it properly.

Foil Insulation Kraft Paper

This insulation type is known as a ‘reflective system’, and it basically tries to bounce heat from it. This compares to more typical insulation which aims to resist heat by reducing the amount of air which can freely move around (forming convection currents).

Reflective insulation is sometimes included as part of other types of insulation (such as the backing of foam insulation boards), but it can be used as a standalone system in hot climates. They are commonly used in the attics of very hot areas, and they can lower cooling costs (such as air conditioners) by 5-10%. They are, however, not very effective as general purpose insulation in cooler climates.

SIPs (Structural Insulated Panels)

SIPs are a newer invention in the construction industry, but they are growing in popularity quickly. They are prefabricated timber boards with rigid board insulation glued between the timber, like a big sandwich. Whilst they cost more to buy than the individual components of a timber frame wall (for example studs, sheathing and insulation), the overall cost is about the same when you factor in labor savings from massively reduced construction times and less jobsite waste.

In terms of SIP R values, the whole SIP wall will have an R-25 value, compared to an R-21.6 rating with standard timber wall construction. The insulation provided is 7-28% more efficient than conventional walls.

Blow-In Cellulose (Wool/Paper) Insulation

An alternative to spray foam insulation which forms a joined-up, continuous insulation material is loose-fill cellulose insulation, whereby organic materials like wool or paper are blown-in to the relevant space (such as a wall cavity or attic). It has an R-3.5/inch rating which is on the low side, however it is an inexpensive option and it is fairly good for the environment as it uses up to 85% recycled wool/paper.

Because it is a loose insulation material, you cannot blow it into open areas such as walls and ceilings without drywall on it. You instead need to make an opening in the closed-off space, and blow the insulation in that way. You can, however, use cellulose insulation in attic spaces because it is a fairly ‘clumpy’ material which will sit on-top of the drywall and around cables, pipes and ducting.

Air Barriers

A nice breeze on a warm day can make a jog feel tolerable, just like wind hitting you during a bicycle ride will cool you. However if you are snuggled up on your couch watching TV and you feel a draught, this will probably make you feel cold. Random air movements around your house – possibly due to wall gaps and small holes which allow air leakage – can account for 30% or more of a home’s heating and cooling costs.

Hence blocking off sources of air leaks is a good first start, however you can also wrap the outside of the building in housewrap (behind the siding) which will help prevent air escaping your home. Just like foil insulation paper, this option will work well in warmer climates – but it is not a substitute for actual insulation, especially in cooler climates.

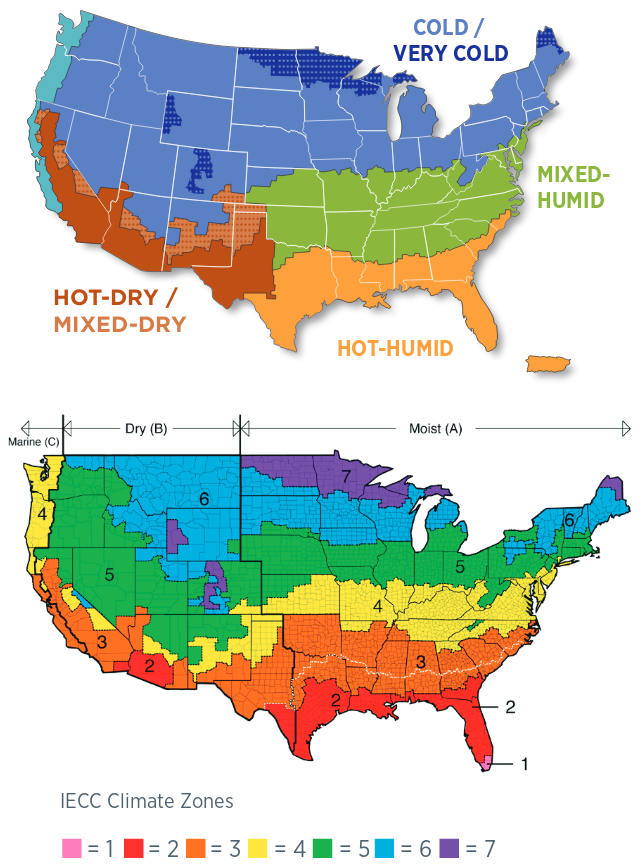

Insulation Thickness Depends On Where You Live

The amount of insulation you need (in each part of your home) depends on which part of America you live in:

Energy Star then helps you to calculate the thickness of insulation you need depending on your zone, which is roughly summed up by saying how much total R value each part of your home needs:

| Location | Loft/Ceiling | Wall | Floor |

|---|---|---|---|

| Zone 1 | 38-49 | 13 | 13 |

| Zone 2 | 38 | 13 | 19 |

| Zone 3 | 38 | 13 | 19 |

| Zone 4 | 38-49 | 13 | 25 |

| Zone 5 | 38-49 | 13 | 30 |

| Zone 6+ | 49 | 13 | 30 |

Based on the overall ‘R value’ you need to achieve, you can then judge the thickness of material you need from the below table:

| Material | 3.5” Thick | 5.25” Thick | 10” Thick |

|---|---|---|---|

| Batts Roll | R-11 | R-17 | R-32 |

| Concrete Block | R-13.5 | R-18 | R-22 |

| Polystyrene Foam Board | R-16 | R-24 | R-43 |

| Polyurethane Foam Board | R-21 | R-32 | R-60 |

| Polyisocyanurate Foam Board | R-24 | R-33 | R-65 |

| Open Cell Spray | R-12 | R-18 | R-35 |

| Closed Cell Spray | R-22 | R-32 | R-62 |

| SIPs | R-15 | R-19 | R-35 |

| Blown-In Cellulose | R-13 | R-20 | R-38 |

(It’s worth pointing out that 12” thick batts insulation achieves R-38 whilst 15” thickness gives R-49)

So in theory, batts insulation within a 3.5” external timber wall is actually not suitable as it only delivers R-11 but you need R-13 in all American climate zones. This is something that you need to think about. Do you:

- ignore the advice and stick with 3.5” walls and batts insulation – which maximizes internal space and offers cheap insulation, whilst only offering slightly less than the recommended level of insulation?

- make your walls thicker and have thicker batts insulation, but losing valuable inches in your internal tiny house layout?

- go with a more effective – but more expensive – insulation material, and stick with 3.5” walls?

Recommended Insulation For Different Parts Of Your House

Now that we have looked at the many different insulation options available, we wanted to give our recommendations for the best insulation to use for each part of your tiny house:

- Exterior Walls: use foam insulation board (any type to suit your requirements and budget) to form a 3.5” thick external wall. This will deliver R-16 to R-21 which is comfortably more than the suggested minimum of R-13.

- Interior Walls: use fiberglass batts insulation at 3.5” thickness, which will only deliver R-11 but this is an internal wall so it is not as important to deliver high R-values. Using batts insulation here will also be cheaper than using more-expensive foam board throughout.

- Roof/Ceiling: the roof loses 25% or more of your house’s heat, so the more insulation you can use the better. Of course, this very much depends on your tiny house layout: if you have a low loft bedroom, you cannot have 15” of batts insulation! Our recommendation here is intentionally vague as a result: use this thickest, most expensive insulation you can.

- Subfloor: if your tiny house is on a fixed foundation (be it wood or concrete), foam insulation board is nearly always the way to go. Batts and blown/spray-in insulation cannot be used as it just gets crushed.